Category: Digital Transformation for Conventional Power Generation Companies

The power generation sector shares a warm relationship with digital technology. The advent of the Industrial Internet of Things (IIoT), artificial intelligence (AI), machine learning (ML), big data, and other ground-breaking technologies have changed the way power generation companies operate. The sector is leveraging remote sensing, networked communication, data aggregation, and virtual monitoring and tracking to optimize power generation. However, there are quite a few companies that are struggling to cope up with the superfast pace of change, demand to increase efficiency, and the undying pressure to cut down costs. This is wreaking havoc on traditional models that these companies have been utilizing. It is time for their decentralized and distributed asset models to evolve and shift to the new centralized operations and maintenance landscape.

Key benefits that conventional power generation companies can expect from digital transformation: |

The power generation sector shares a warm relationship with digital technology. The advent of the Industrial Internet of Things (IIoT), artificial intelligence (AI), machine learning (ML), big data, and other ground-breaking technologies have changed the way power generation companies operate. The sector is leveraging remote sensing, networked communication, data aggregation, and virtual monitoring and tracking to optimize power generation. However, there are quite a few companies that are struggling to cope up with the superfast pace of change, demand to increase efficiency, and the undying pressure to cut down costs. This is wreaking havoc on traditional models that these companies have been utilizing. It is time for their decentralized and distributed asset models to evolve and shift to the new centralized operations and maintenance landscape.

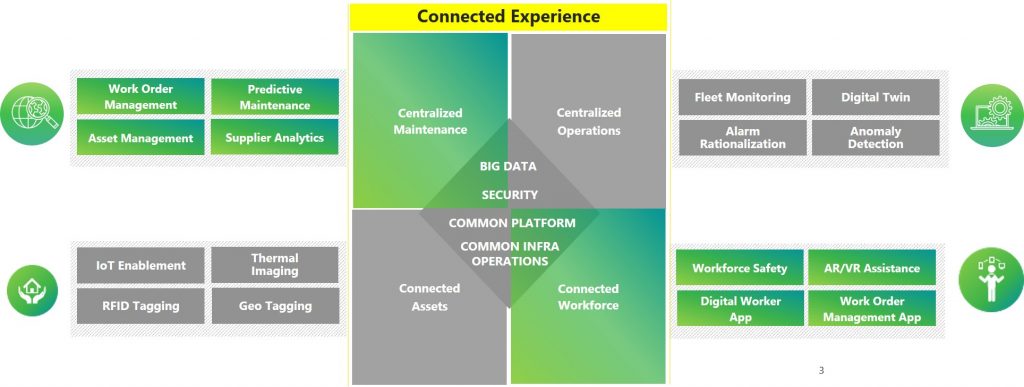

Implementing short-term changes to respond to immediate demands will hinder value creation in the long run. A robust digital transformation strategy and roadmap that promises a connected experience across the power generation lifecycle is the best way forward. In line with this, Happiest Minds’ digital transformation framework offers power generation companies a reliable path for improving business processes and deriving greater returns on investments with connected assets, a connected workforce, centralized operations, and centralized maintenance.

Offerings

- Connected Assets

-

By connecting the wide array of distributed assets in the complex ecosystem and transforming machines and equipment into smart assets, Happiest Minds helps power generation companies achieve end-to-end asset tracking, cost optimization, risk reduction, and flexibility in operations. In addition to location tracking of assets, they are able to: analyze if their equipment is working at the optimum level, gauge what needs to be done to extend the lifespan of assets, etc. Happiest Minds’ connected asset use cases include:

- IoT Enablement

- Thermal imaging

- RFID tagging

- Geotagging

- Connected Workforce

-

We help power generation plants transition to a connected digital workforce with the right approach and suitable application of technology. We enable them to leverage the power of augmented reality (AR), virtual reality (VR), wearables, and more to enhance efficiency, productivity, and worker safety. Our connected workforce use cases include:

- Workforce safety

- AR/VR assistance

- Digital worker app

- Work order management app

- Centralized Maintenance

-

As maintenance techniques and technologies evolve, it is imperative for power generation plants to upgrade their planning and decision-making processes. We help them transition from responsive maintenance to predictive and preventive maintenance of assets and equipment. Happiest Minds enables plants to apply the latest monitoring techniques in their equipment and machine efficiency optimization programs, facilitating significant improvements in asset performance while bringing down maintenance costs. Our centralized maintenance use cases include:

- Work order management

- Predictive maintenance

- Asset management

- Supplier analytics

- Centralized Operations

-

Happiest Minds enables power generation companies to monitor equipment and fleet, forecast equipment failure, dispatch maintenance, track employee activity and safety, and more. We facilitate unified operations powered by intelligent systems and the latest in technology such as the digital twin, to help owners enhance control over their plants, improve worker efficiency, boost asset performance, rationalize and manage abnormal situations, and improve decision-making ability. Our centralized operations use cases include:

- Alarm rationalization

- Digital twin

- Fleet monitoring

- Anomaly detection