Category: Energy & Utilities

In the present digital era, the industrial world—and in particular, the energy and utilities sector—has been witnessing exponential growth in data. Unfortunately, despite the availability of a huge amount of valuable information, a major portion of the data is traditionally siloed across business units due to which companies involved in conventional power generation, renewable energy generation, power transmission and distribution, retail energy services and water companies are unable to optimize their processes. They are struggling to monitor plants, transmission lines, sub-stations, power meters, water pipelines or effluents efficiently, and maintain and operate them centrally—with minimal local presence and requirements-based dispatching. Digital intervention for extracting wealth out of the siloed data from multiple distributed assets and putting it to work to create a connected experience across functions is what businesses in the energy and utilities domain need.

Benefits that energy and utilities companies can derive from digital transformation: |

In the present digital era, the industrial world—and in particular, the energy and utilities sector—has been witnessing exponential growth in data. Unfortunately, despite the availability of a huge amount of valuable information, a major portion of the data is traditionally siloed across business units due to which companies involved in conventional power generation, renewable energy generation, power transmission and distribution, retail energy services and water companies are unable to optimize their processes. They are struggling to monitor plants, transmission lines, sub-stations, smart meters efficiently, and maintain and operate them centrally—with minimal local presence and requirements-based dispatching. Digital intervention for extracting wealth out of the siloed data from multiple distributed assets and putting it to work to create a connected experience across functions is what businesses in the energy and utilities domain need.

Leveraging the latest in technology to automate workflows and processes can deliver greater value across all stages in the user journey:

- Digital transformation in plants, transmission lines, sub-stations, and consumer homes

- Efficient daily operations

- Enhanced workforce management

- Optimized performance

- Improved safety

- Reduced operations and maintenance costs.

- Effective effluent treatment & compliance with standards

- Smart metering

- Predictive Maintenance

- Chatbot/ Digital Assistant for customer service

- Outage management

- End-End integration of sensors/assets, enterprise systems to help transform from a traditional utility provider to a digital player

Together, big data, Internet of things (IoT), artificial intelligence (AI), machine learning (ML), augmented reality (AR), virtual reality (VR), and other revolutionary technologies offer the promise of a brighter future for energy and utilities companies.

Happiest Minds evaluates current operational processes and IT architecture and then helps clients in the energy and utilities segment utilize state-of-the-art technologies to enjoy a connected experience with connected assets and a connected workforce, leading to centralized maintenance and centralized operations. Developing solutions with a common platform ensures a seamless and centralized experience for all stakeholders. In addition to new developments, Happiest Minds helps integrate legacy systems, bringing them on to a common platform to enable smooth management without the need of accessing multiple websites and portals to track different assets and operations. CXO-level management dashboards allow decision makers to analyze investments, the total cost of ownership of each of their sites, worker productivity, and more.

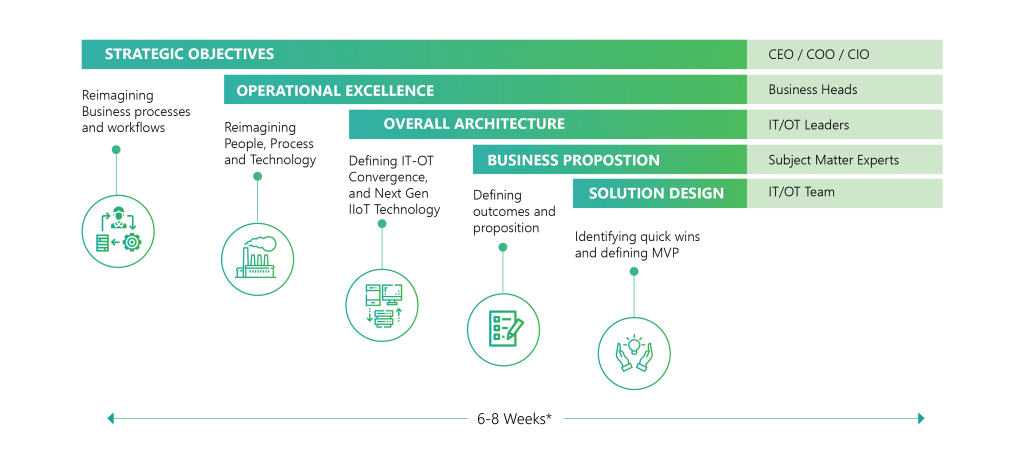

We work very closely with our clients and follow a systematic approach, powered by our proven consulting framework, to bring about digital transformation. The framework comprises pre-assessment questionnaires, stakeholder discovery sessions, workshops for reviewing findings, analyzing value creation opportunities, defining the technology strategy and execution approach, and finally, developing an optimum time-based implementation roadmap for new initiatives to ensure early success outcomes. Comprehensive interview sessions, workshops, and plant and site visits help us to assess technological gaps and propose a customized digital roadmap best suited to our client’s requirements. In a span of 6-8 weeks, we enable transformation across all levels and functions of the organization.

CREATING A DIGITAL TRANSFORMATION ROADMAP

USE CASE SCENARIOS

- Sourcing of raw materials

-

We automate the procurement process for sourcing raw materials or hardware assets that go into generation plants, transmission lines, and substations, helping enterprises save cost and effort. Furthermore, we help them take advantage of AI and ML technology for supplier analytics, enabling decision makers to review and choose the best suppliers with reliable materials.

- Demand and forecasting

-

We leverage state-of-the-art AI and ML tools to help plants forecast energy demand accurately, enabling them to generate energy optimally. By equipping virtual power plants (VPPs) with forecasting controls, demand response, distributed generation, and mixed assets, Happiest Minds facilitates grid optimization and distributed energy resource aggregation.

- Planning and scheduling

-

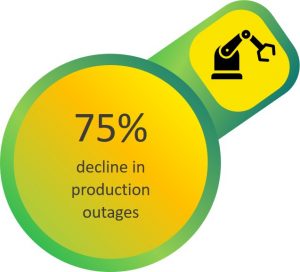

Our predictive-maintenance-based planning solutions not only help teams schedule daily work but also assist in predicting the ideal time and condition for carrying out repair work so as to cause the least possible impact on business. We leverage AI and ML to help plants analyze low-demand days, enabling them to optimize the total cost of ownership of repair and perform outage work economically based on actionable data insights.

- Asset monitoring

-

IoT and radio-frequency identification (RFID) have redefined asset management and tracking in connected plants. Through IoT-enabled and RFID-tag-based tracking, we help plants monitor asset performance and predict failure. With sensor readings that offer accurate real-time information, we help decision makers make informed choices at the right time.

- Maintenance

-

Our solutions around AR, VR, and handheld devices have been empowering maintenance crews in plants dealing with renewable energy, power generation, transmission, and distribution. AR and VR simplify tracking and inspection of tens of thousands of parts, identification of errors, and locating the exact source of the error. They also assist maintenance crews in following the standard operating procedure via visual guidance.

- Operations

-

We help plants set up centralized control rooms to monitor multiple plants across locations or even dispatch maintenance—all from a single place. We help companies in the energy and utilities sector explore the limitless power of technology in operations. We leverage wearable device technology to help them track and confirm worker safety. When a worker repairing or inspecting parts is at risk, or suffers an injury or a fall, readings from these wearable devices could detect the situation and alert authorized personnel to take immediate action.